Our technology

- Medium-frequency melting units with a capacity of 2 x 4 tons

- Furan pressing technology

- Semi-automatic carousel line Omega

- Cold core production method

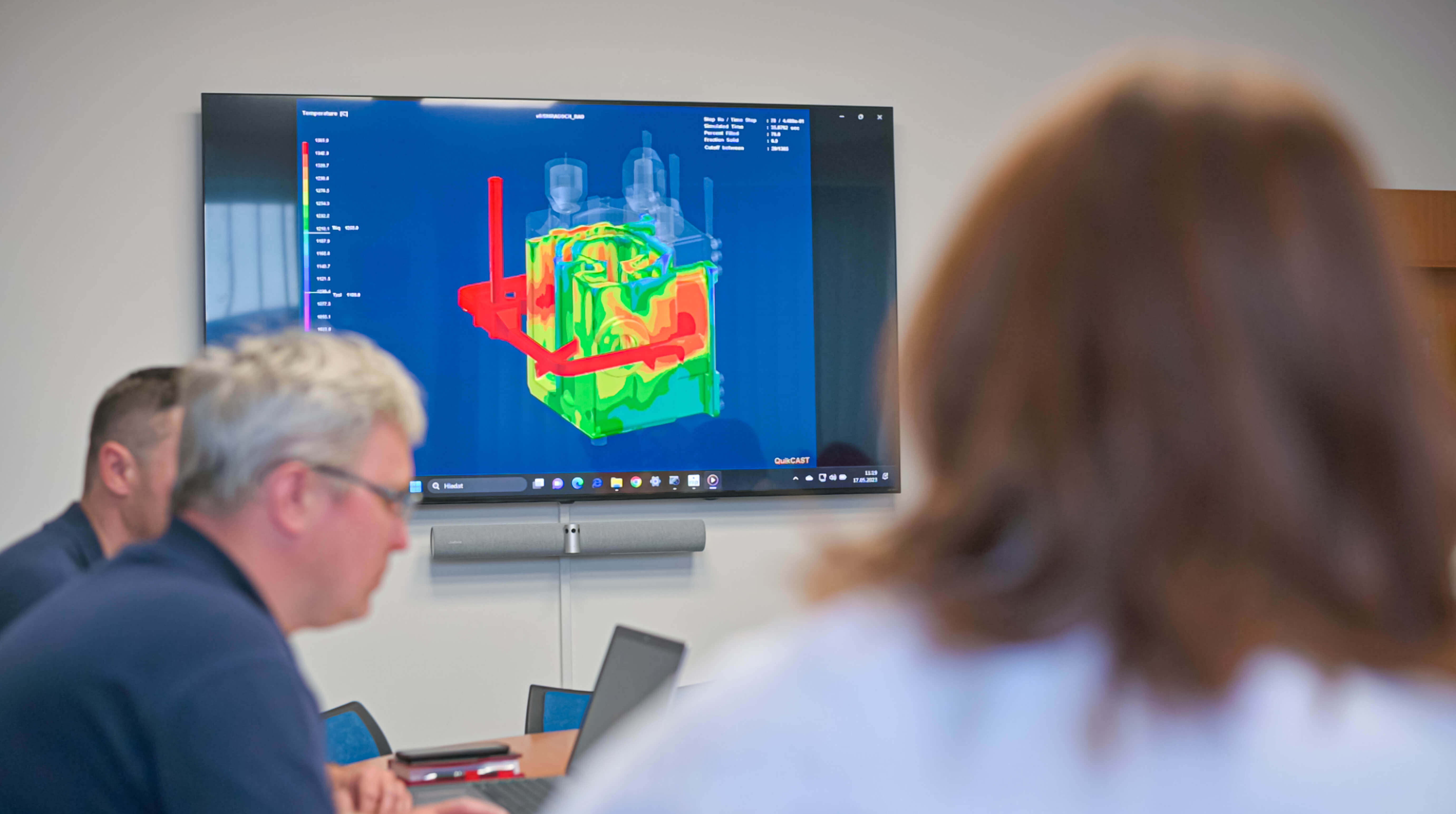

- Simulation of the cooling process using Mecast software

- Modification of ductile iron by core wire injection equipment

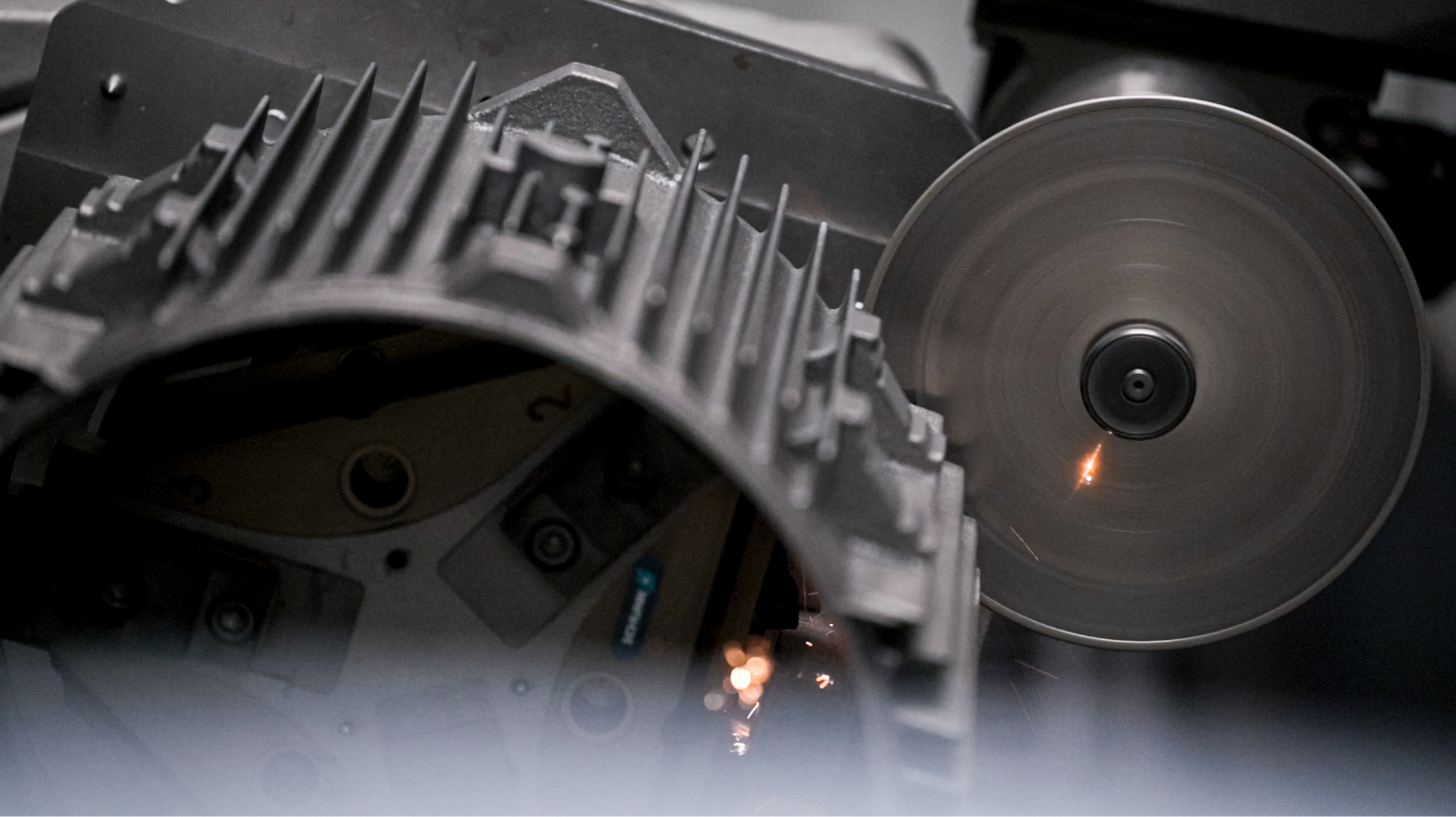

- Blasting, mechanical and manual grinding of castings

- Robotic grinding

- Casting simulation